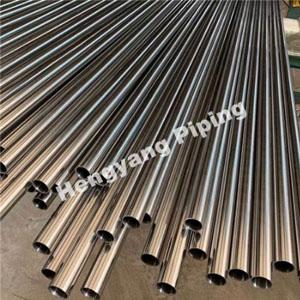

Bright Annealed Tube vs. Open Air Annealed Tube

Overview of Bright Annealed Tubes

Definition and Characteristics

Bright annealed tubing has a smoother surface, which imbues the component with better resistance to pitting corrosion. It also provides a better sealing surface when tube fittings, which seal on the outside diameter, are used for connections.

Bright annealing is an annealing process performed in a vacuum or a controlled atmosphere containing inert gases (such as hydrogen). This controlled atmosphere reduces the surface oxidation to a minimum which results in a brighter surface and a much thinner oxide layer.

Common Applications

Bright annealed tubes are widely used in industries where cleanliness and aesthetics are paramount. Applications include:

- Food and Beverage: Used in processing equipment where hygiene is critical.

- Pharmaceuticals: Employed in manufacturing processes to prevent contamination.

- Aerospace and Automotive: Utilized for components requiring high strength and resistance to corrosion.

Overview of Open Air Annealed Tubes

Definition and Characteristics

Open air annealed tubes are those that are annealed in an open atmosphere, which can expose them to oxygen and other elements during the heating process. As a result, these tubes may have a less smooth surface compared to bright annealed tubes and might show some oxidation or discoloration.

Common Applications

Open air annealed tubes are often used in applications where surface finish is not critical. Common uses include:

- Structural Applications: Used in construction and manufacturing where appearance is less of a concern.

- Piping Systems: Suitable for plumbing and other utility applications.

- General Manufacturing: Utilized in products that do not require a polished finish.

Key Differences Between Bright Annealed and Open Air Annealed Tubes

Manufacturing Processes

The manufacturing processes for both types of tubes differ significantly. Bright annealed tubes undergo controlled atmosphere annealing, whereas open air annealed tubes are exposed to the atmosphere. This difference affects the final product's surface quality and properties.

Surface Finish Quality

Bright annealed tubes boast a smooth, polished surface finish due to the controlled environment during the annealing process. In contrast, open air annealed tubes may have a rougher surface with possible oxidation, which can affect their appearance and performance in certain applications.

Mechanical Properties

Bright annealed tubes typically exhibit better mechanical properties, including increased ductility and strength, owing to the refined microstructure resulting from the controlled annealing process. Open air annealed tubes may have less uniform properties due to exposure to atmospheric conditions.

Corrosion Resistance

The corrosion resistance of bright annealed tubes is superior due to the absence of surface contaminants. Open air annealed tubes may be more susceptible to rust and corrosion due to their exposure to oxygen during processing.

Advantages and Disadvantages

Bright Annealed Tubes: Pros and Cons

Pros:

- Excellent surface finish.

- High corrosion resistance.

- Suitable for sensitive applications (food, pharmaceutical).

Cons:

- Generally higher cost due to the controlled process.

- Limited to specific applications.

Open Air Annealed Tubes: Pros and Cons

Pros:

- Lower manufacturing costs.

- Versatile for general applications.

Cons:

- Inferior surface finish.

- Less corrosion resistance.

- Not suitable for sensitive environments.

Choosing the Right Tube for Your Application

When selecting between bright annealed and open air annealed tubes, consider factors such as:

- Application requirements: Cleanliness, aesthetics, and exposure to harsh conditions.

- Budget constraints: The cost difference between the two types of tubes.

- Mechanical properties needed: Strength and ductility requirements.

Conclusion

In summary, the choice between bright annealed and open air annealed tubes largely depends on the specific requirements of your application. Bright annealed tubes are ideal for environments where cleanliness and surface finish are critical, while open air annealed tubes can be more cost-effective for less demanding applications. Understanding these differences can help ensure that you select the most suitable type of tube for your needs.

FAQs

What is the primary difference between the two types of tubes?

The primary difference lies in the annealing process: bright annealed tubes are processed in a controlled atmosphere, resulting in a superior surface finish, while open air annealed tubes are exposed to the environment, leading to potential oxidation.

Can bright annealed tubes be used in high-temperature applications?

Yes, bright annealed tubes can withstand high temperatures, but it’s essential to consider the specific material properties for the intended application.

How does surface finish affect performance?

A smoother surface finish typically enhances corrosion resistance and is crucial for applications requiring cleanliness, such as in the food and pharmaceutical industries.

Are open air annealed tubes suitable for outdoor applications?

Yes, but they may require additional protective coatings to mitigate corrosion risk due to exposure to the elements.

What materials are commonly used for these tubes?

Common materials include stainless steel, carbon steel, and other alloys, depending on the specific application and required properties.

How do I maintain these tubes for longevity?

Regular cleaning and inspections can help maintain the integrity of both types of tubes. For open air annealed tubes, applying protective coatings can also extend their lifespan.