How Does 254SMO Compare to Super Duplex Stainless Steels?

254SMO (UNS S31254, ASTM F44, 1.4547) is a so-called super austenitic stainless steel. By increasing the molybdenum content to 6%, it achieves a pitting resistance equivalent number (PREN) > 43, which is similar to that of a super duplex stainless steel (SDSS).

When comparing 254SMO to super duplex stainless steels (SDSS), it stands out for being non-magnetic and potentially easier to weld. It also offers a broader operating temperature range. However, 254SMO is considerably more expensive due to its higher nickel and molybdenum content and has significantly lower strength compared to SDSS. Therefore, 254SMO is primarily used in applications where SDSS is not suitable.

This includes applications at lower temperatures (>-50°C) where the impact strength of SDSS decreases, or at higher temperatures (>-250°C) where there is a risk of forming harmful phases if exposed for extended periods.

Composition and Properties

Chromium (Cr): 19.5-20.5%

Nickel (Ni): 17.5-18.5%

Molybdenum (Mo): 6.1-6.5%

Nitrogen (N): 0.18-0.22%

Copper (Cu): 0.5-1.0%

Key Features

Corrosion Resistance: 254SMO excels in chloride-rich environments, outperforming many other stainless steels, including some super duplex grades.

High Strength: Despite being an austenitic stainless steel, it offers tensile strength and toughness comparable to some duplex steels.

Weldability: It is highly weldable and can be used in fabricated structures without significant loss of strength or resistance to corrosion.

Cost: Generally more expensive due to its high molybdenum and nickel content, which are critical for its performance but also add to its cost.

Popular Applications for 254SMO

254SMO is utilized in various demanding applications due to its exceptional resistance to corrosion and ability to operate in extreme environments. Some popular applications include:

- Equipment in pulp bleaching plants: 254SMO's resistance to chlorides makes it ideal for the harsh conditions in pulp bleaching.

- Components in gas cleaning systems: Its robustness and corrosion resistance are crucial for the aggressive environments in gas cleaning processes.

- Seawater handling equipment: This includes heat exchangers, ballast water systems, firefighting systems, and cooling water systems, where 254SMO's ability to withstand salty conditions is vital.

Additionally, 254SMO and other super austenitic stainless steels are specified for marine scrubbers, as their intermittent use can result in operating temperatures exceeding 250°C.

However, super duplex stainless steels (SDSS) have proven effective in flue gas desulfurization systems for power stations. These systems benefit from SDSS because their continuous operation generally results in lower temperatures overall.

In water treatment systems, such as reverse osmosis (RO) and desalination, super austenitics like 254SMO are often replaced by super duplex stainless steels due to their superior strength and cost-effectiveness in these applications.

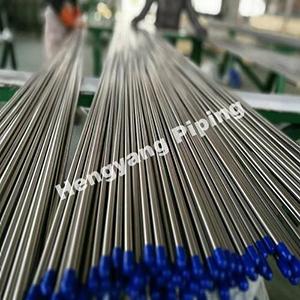

UNS 31254 stainless steel pipes

Exploring Super Duplex Stainless Steels

Composition and Properties

Super Duplex Stainless Steels are known for their dual-phase structure, consisting of approximately equal parts austenite and ferrite. This unique structure imparts high strength and excellent corrosion resistance. Key elements in their composition typically include:

Chromium (Cr): 24-26%

Nickel (Ni): 6-8%

Molybdenum (Mo): 3-5%

Nitrogen (N): 0.24-0.32%

Key Features

Superior Strength: Super duplex steels offer significantly higher yield strength than 254SMO, making them suitable for structural applications where high mechanical strength is required.

Corrosion Resistance: They provide excellent resistance to general corrosion, pitting, and stress corrosion cracking, especially in seawater and other chloride-containing environments.

Cost Efficiency: While still more costly than standard stainless steels, super duplex steels generally offer a more cost-effective solution than 254SMO due to their lower nickel content.

Weldability: Welding requires more care compared to 254SMO to prevent loss of mechanical properties and corrosion resistance.

Comparative Analysis

Corrosion Resistance

When comparing 254SMO and Super Duplex Stainless Steels in terms of corrosion resistance, 254SMO generally takes the lead in environments with high chloride concentrations and acidic conditions. The high molybdenum content in 254SMO provides superior pitting and crevice corrosion resistance. In contrast, super duplex steels perform exceptionally well in a broader range of environments, including those with moderate chloride levels and where general corrosion resistance is paramount.

Strength and Durability

Super Duplex Stainless Steels boast nearly double the yield strength of 254SMO, making them ideal for high-stress applications where mechanical performance is critical. This makes them preferable for structural components in industries such as oil and gas, where both strength and resistance to harsh environments are required.

Choosing the Right Material

Selecting between 254SMO and Super Duplex Stainless Steels depends on the specific requirements of the application. Factors such as environmental conditions, mechanical stress, and budget constraints will guide the decision. In environments with extreme corrosive conditions, 254SMO's superior corrosion resistance is invaluable. Conversely, for applications demanding high strength and durability in moderately corrosive environments, super duplex steels are often the preferred choice.

Conclusion

Both 254SMO and Super Duplex Stainless Steels are indispensable in industries facing challenging conditions. Understanding their unique properties and applications ensures that the right material is chosen for optimal performance and cost-efficiency.

If you are looking for a reliable supplier of high-quality stainless steels or need further assistance in choosing the right material for your project, please contact us. Our team is here to provide expert guidance and supply you with the best materials for your needs.