S31254 Pipe: A Comprehensive Guide

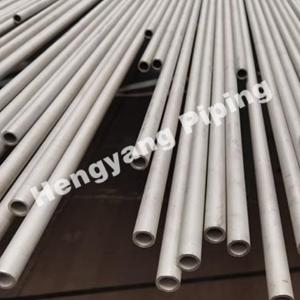

6 Mo (UNS S31254) pipes is a super austenitic stainless steel with a high level of molybdenum and nitrogen, providing high resistance to pitting and crevice corrosion as well as high strength compared with conventional austenitic stainless steels such as 316L.

UNS S31254, also known as 6 Mo, is a stainless steel alloy that is highly resistant to corrosion and can withstand high pressures and stress corrosion cracking. It has a high level of nitrogen and molybdenum, and is often used in the chemical, marine, and oil and gas industries.

UNS S31254 has many properties, including: High ductility, Impact strength, Resistance to pitting and crevice corrosion, Can be used in sub-zero temperatures, and Can be used in corrosive environments.

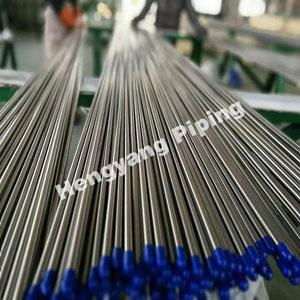

UNS S31254 pipes are used in applications that require extreme protection against corrosion, heat, and pressure. Some examples of applications include:

Seawater systems such as sea-water cooling, cooling water piping, ballast water systems, and fire-extinguishing systems

Hydraulic and instrumentation hoses

Equipment in pulp bleaching facilities

Components for gas cleaning systems

Tanks and pipes for chemicals with high halide

Understanding s31254 Pipe

S31254 pipe stands out as a beacon of reliability, durability, and versatility. Engineered to withstand harsh environments and demanding applications, s31254 pipe, also known as alloy 254 pipe, boasts a unique composition that renders it highly resistant to corrosion, erosion, and extreme temperatures. This article delves deep into the intricacies of s31254 pipe, exploring its properties, applications, and why it's the preferred choice for various industries worldwide.

Composition and Properties

Alloy 254: The Foundation of Excellence

At the core of s31254 pipe lies a meticulously crafted alloy composition. Comprising primarily of chromium, molybdenum, and nitrogen, alloy 254 exhibits exceptional corrosion resistance, even in highly corrosive environments such as those containing chloride ions. Additionally, its high levels of nickel and molybdenum contribute to its superior resistance to both pitting and crevice corrosion, making it an ideal choice for applications where traditional stainless steels fall short.

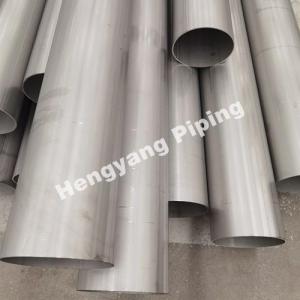

Robust Mechanical Properties

Beyond its corrosion-resistant properties, s31254 pipe also boasts impressive mechanical characteristics. With a high tensile strength and excellent impact resistance, this alloy maintains structural integrity even under extreme pressures and temperatures. Its ductility ensures ease of fabrication and installation, allowing for seamless integration into various piping systems without compromising performance or longevity.

Applications Across Industries

Oil and Gas Sector

In the oil and gas industry, where operational efficiency and asset longevity are paramount, s31254 pipe shines as a preferred solution for transporting corrosive fluids and gases. From offshore platforms to onshore refineries, its ability to withstand aggressive media and harsh environmental conditions makes it indispensable for critical applications such as subsea pipelines, gas processing facilities, and chemical injection systems.

Chemical Processing

Within the realm of chemical processing, where corrosive chemicals and aggressive solvents are commonplace, s31254 pipe emerges as a stalwart defender against degradation and system failures. Its resistance to a wide range of acids, alkalis, and organic compounds ensures the integrity of process lines, reactors, and storage tanks, thereby safeguarding both personnel and the environment against potential hazards.

Marine Engineering

In marine engineering applications, where exposure to saltwater, brine, and marine organisms poses significant challenges to traditional materials, s31254 pipe stands as a beacon of reliability. Whether utilized in seawater desalination plants, offshore drilling rigs, or shipboard piping systems, its corrosion-resistant properties and durability ensure optimal performance and longevity in maritime environments.

Conclusion: Partnering with Excellence

In conclusion, s31254 pipe epitomizes excellence in the realm of industrial piping, offering unparalleled corrosion resistance, robust mechanical properties, and versatility across a myriad of applications. As industries continue to evolve and demand solutions capable of withstanding increasingly harsh conditions, alloy 254 remains a steadfast ally, providing peace of mind, reliability, and performance excellence.

For inquiries about s31254 pipe and how it can elevate your operations to new heights of efficiency and reliability, don't hesitate to contact us. As a leading supplier of premium piping solutions, we are committed to delivering excellence and exceeding your expectations at every turn.