Ferritic Stainless Steel - Composition, Properties, and Uses

In the world of stainless steels, ferritic stainless steel stands as a remarkable player, exhibiting a unique set of properties, compositions, and applications that set it apart from other steel types. This article delves deep into the realm of ferritic stainless steel, shedding light on its composition, properties, and versatile uses.

Understanding Ferritic Stainless Steel

Ferritic stainless steel, one of the major categories of stainless steel alloys, is known for its high chromium content, which imparts excellent corrosion resistance to this alloy. Chromium, often present in concentrations ranging from 11% to 30%, forms a passive oxide layer on the steel's surface, rendering it resistant to various corrosive environments. This passive layer acts as a shield, preventing the underlying steel from reacting with its surroundings.

Composition

The key composition elements of ferritic stainless steel include chromium, of course, along with iron. In addition, elements like carbon, silicon, and sometimes manganese are also present in controlled amounts. Unlike austenitic stainless steels, which contain nickel, ferritic stainless steels have minimal to no nickel content. This characteristic makes ferritic stainless steel less expensive than its counterparts, contributing to its wide industrial application.

Properties

1. Corrosion Resistance: As mentioned, the high chromium content is the prime contributor to the impressive corrosion resistance of ferritic stainless steel. This makes it an ideal choice for various applications where exposure to moisture or corrosive substances is prevalent.

2. Magnetic Nature: UNS S34709 ferritic stainless steel is generally magnetic, a property attributed to its microstructure. This magnetic behavior opens up doors for its use in applications where magnetic properties are desirable.

3. Heat Resistance: While not as heat-resistant as austenitic stainless steels, ferritic variants still exhibit reasonable heat resistance, making them suitable for applications involving moderately elevated temperatures.

4. Strength and Toughness: Ferritic stainless steel showcases good mechanical properties, with a balance of strength and toughness that suits various engineering needs.

5. Formability: These steels are easily formable, allowing manufacturers to shape them into a wide array of products, ranging from kitchen utensils to automotive components.

Applications

Ferritic stainless steel's unique combination of properties opens up a myriad of applications across industries:

1. Automotive Industry: The magnetic property of ferritic stainless steel finds applications in automotive components like exhaust systems, catalytic converters, and decorative trims.

2. Architecture and Construction: Its corrosion resistance makes it an excellent choice for architectural elements exposed to varying weather conditions, such as roofing, cladding, and structural components.

3. Kitchen Equipment: The formability and corrosion resistance of ferritic stainless steel make it a favorite for manufacturing kitchen sinks, utensils, and appliances.

4. Industrial Equipment: This steel type is used in equipment and machinery exposed to mildly corrosive environments, such as chemical processing equipment and storage tanks.

5. Consumer Goods: From washing machine drums to water heaters, ferritic stainless steel's durability and corrosion resistance make it a popular choice for various consumer goods.

Conclusion

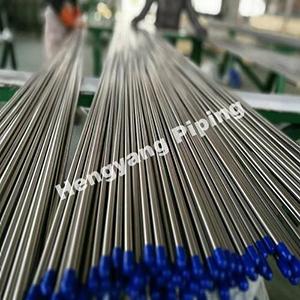

In the realm of stainless steels, ferritic stainless steel pipes stands tall with its unique properties, diverse compositions, and wide-ranging applications. Its corrosion resistance, magnetic nature, and overall mechanical characteristics make it an attractive choice for industries seeking durable and cost-effective materials. As technology continues to advance, ferritic stainless steel continues to find innovative applications, solidifying its place as a vital player in the world of metallurgy.

ZHEJIANG HENGYANG PIPING EQUIPMENT CO., LTD. ( HPE) is the global window of Chinese reputed manufacturers, dealing professionally in exporting business for them, exporting all the products manufactured by them, including seamless I welded pipes and tubes, fittings and flanges, round bars and forgings. As well as manufacturing to orders, the company also keep a wide range products in stock which have been strictly inspected and are ready for quick shipment.

The main materials the company adopts are stainless steel, (super) duplex steel, corrosion-resistant alloys, nickel alloys.

If you want to read more information about ferritic stainless steel pipes, just visit -->https://www.hengyangpiping.com/pipe-tube-fin-tube-fitting-flange-forging-sheet-strip.html