What Is the 904L Stainless Steel Pipe?

904L stainless steel is a low-carbon austenitic stainless steel known for its enhanced corrosion resistance. Its chemical composition includes higher percentages of chromium (19-23%) and molybdenum (4-5%) compared to 316L stainless steel. This gives 904L superior durability and resistance to corrosion. Many people recognize 904L stainless steel as the material used in Rolex watches, highlighting its high quality and durability. The same properties that make it ideal for luxury watches also make it highly beneficial for seawater applications.

The material has 23% nickel, 19% chromium, carbon, manganese, silicon, phosphorus, sulfur and 4% molybdenum in the composition with nitrogen in 0.1% as well. The 904L Stainless Steel Tube gets the corrosion resistance and the strength from the composition. The material has 220MPa yield strength and 490MPa tensile strength. The material also has 70-90 Rockwell B hardness score. The Stainless Steel 904L Tubing belongs to ASTM B673 specification.

Chemical Composition

The unique chemical composition of 904L stainless steel includes:

- Chromium (19-23%): Enhances corrosion resistance.

- Nickel (23-28%): Provides excellent toughness and stability.

- Molybdenum (4-5%): Increases resistance to pitting and crevice corrosion.

- Copper (1-2%): Improves resistance to sulfuric acid.

This blend of elements ensures that 904L stainless steel can withstand harsh environments that would typically cause other grades of stainless steel to deteriorate.

Key Features of 904L Stainless Steel Pipe

Superior Corrosion Resistance

One of the primary advantages of 904L stainless steel pipe is its superior corrosion resistance. This material excels in environments that are acidic and chloride-rich, where it resists pitting and crevice corrosion better than other stainless steel grades. Its resistance to sulfuric acid makes it a preferred choice in chemical processing industries.

High Strength and Toughness

904L stainless steel offers high tensile strength and toughness, even at elevated temperatures. This makes it suitable for applications where mechanical stress is a concern, providing reliable performance without compromising structural integrity.

Excellent Weldability and Formability

Despite its high alloy content, 904L stainless steel pipe maintains excellent weldability and formability. This allows for easy fabrication and installation, making it a versatile choice for various industrial applications. Welding can be performed using all conventional methods, ensuring robust and durable joints.

Longevity and Low Maintenance

Due to its exceptional resistance to corrosion and wear, 904L stainless steel pipe has a long service life with minimal maintenance requirements. This durability translates to cost savings over time, as the need for replacements and repairs is significantly reduced.

Applications of 904L Stainless Steel Pipe

Chemical Processing Industry

The chemical processing industry demands materials that can withstand highly corrosive environments. 904L pipe is extensively used in the production and handling of sulfuric acid, phosphoric acid, and acetic acid. Its resistance to these aggressive chemicals ensures the safe and efficient operation of processing equipment.

Oil and Gas Industry

In the oil and gas sector, equipment is often exposed to harsh conditions, including high pressure and corrosive substances. 904L stainless steel pipe is ideal for use in pipelines, heat exchangers, and other critical components, providing reliability and longevity in offshore and onshore applications.

Marine Applications

The marine environment is notoriously corrosive due to the presence of saltwater. 904L stainless steel pipe is highly resistant to seawater corrosion, making it suitable for shipbuilding, desalination plants, and other marine applications where durability and resistance to the elements are crucial.

Pharmaceutical and Food Industries

In the pharmaceutical and food industries, maintaining hygienic conditions is paramount. 904L stainless steel pipe is favored for its non-reactive properties and ease of cleaning. It is used in the manufacturing of equipment that comes into contact with products, ensuring purity and safety.

Environmental Equipment

Environmental technology, such as wastewater treatment and pollution control systems, benefits from the use of 904L stainless steel pipe. Its resistance to corrosion by various chemicals and pollutants ensures the longevity and effectiveness of environmental equipment.

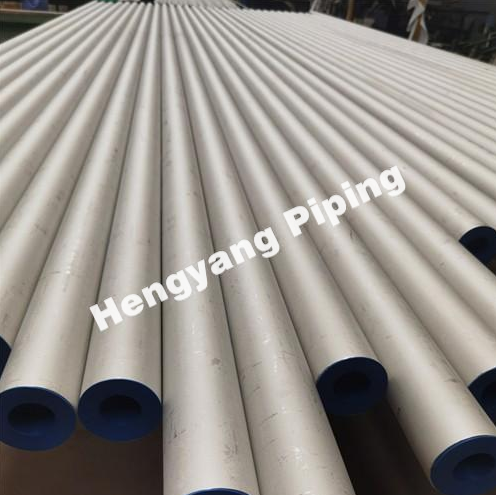

Why Choose HENGYANG as Your 904L Stainless Steel Pipe Supplier?

At HENGYANG, we specialize in providing high-quality 904L stainless steel pipes tailored to meet the stringent demands of various industries. Our products are manufactured using the latest technology and adhere to international standards, ensuring superior performance and reliability.

Exceptional Customer Service

We pride ourselves on offering exceptional customer service, from initial consultation to after-sales support. Our team of experts is always ready to assist you in selecting the right products for your specific needs.

Competitive Pricing and Timely Delivery

We understand the importance of cost-effectiveness and timely delivery in today's competitive market. HENGYANG offers competitive pricing without compromising on quality, and we ensure that your orders are delivered on time, every time.

For more information about our products or to place an order, contact us today. As a leading supplier of 904L stainless steel pipes, HENGYANG is committed to providing solutions that exceed your expectations.