HENGYANG PIPING specializes in high-performance duplex and super duplex stainless steel pipes engineered to thrive in extreme conditions. Combining 50% austenitic and 50% ferritic microstructures, our duplex steel solutions deliver twice the yield strength of standard stainless steels while resisting chloride stress corrosion, pitting, and cracking. Certified to ASTM A790, ASME SA789, and global standards, our welded steel pipes are trusted in offshore oil rigs, chemical plants, and desalination systems across the Middle East, Europe, and Asia-Pacific.

Duplex stainless steel pipes features

1. Standard Duplex Stainless Steel Pipes

Grades: S32205 (2205), S32304 (Lean Duplex)

Key Properties:

Yield Strength: 450-550 MPa (2x Austenitic 304/316)

Corrosion Resistance: Excellent against chlorides, sulfides, and acidic media.

Temperature Range: -50°C to 300°C (avoid prolonged high-temp embrittlement).

Standards: ASTM A790, EN 10216-5.

2. Super Duplex Stainless Steel Pipes

Grades: S32750 (2507), S32760 (Zeron 100)

Key Properties:

Enhanced Alloy Content: 25% Cr, 7% Ni, 4% Mo, 0.3% N (PREN >40).

Ultimate Strength: 800-1000 MPa tensile strength for high-pressure systems.

Applications: Subsea umbilicals, chemical tankers, sour gas pipelines.

Certifications: NACE MR0175 for sulfide stress cracking resistance.

3. Specialized Duplex Solutions

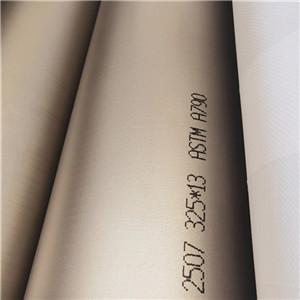

Large-Diameter Super Duplex Pipes: Up to 325x13 mm (ASTM A790) for structural and marine applications.

Welded & Seamless Options: Precision ERW (Electric Resistance Welded) and cold-drawn seamless duplex steel tubes.

ADVANTAGES OF HENGYANG DUPLEX STEEL PIPES

Cost Efficiency: Reduced nickel/molybdenum content vs. austenitic grades lowers material costs.

Weight Savings: High strength enables thinner walls (e.g., 40% lighter vs. 316L).

Weldability: Compatible with TIG, MIG, and SAW processes; minimal post-weld heat treatment.

Sustainability: 100% recyclable with extended lifecycle in harsh environments.

INDUSTRY APPLICATIONS

Oil & Gas:

Subsea pipelines (S32750 super duplex).

Downhole tubing for sour gas wells (H₂S-resistant S32205).

Chemical Processing:

Acid transport systems (Alloy 2507).

Heat exchangers (Lean Duplex S32304).

Marine Engineering:

Seawater cooling pipes, ship hulls (PREN >40 grades).

Desalination plant reverse osmosis (RO) tubes.

Infrastructure:

Bridges, coastal structural supports (high-strength 2205).

WHY CHOOSE HENGYANG PIPING?

Global Compliance & Traceability

Full MTRs (Mill Test Reports) with EN 10204 3.1/3.2 certification.

NACE MR0103/MR0175 compliance for oilfield sour service.

Custom Engineering Support

Material Optimization: Tailor chemistry (e.g., nitrogen-enriched S32760) for specific corrosion/load requirements.

Bespoke Sizes: Roll-formed or welded pipes up to 325mm OD with custom wall thickness.

Competitive Pricing & Fast Delivery

Transparent quotes based on grade, size, and volume (bulk discounts available).

15,000+ metric tons of ready stock for 48-hour dispatch to global ports.