Precision Tube: What It Is and What It Is Used For

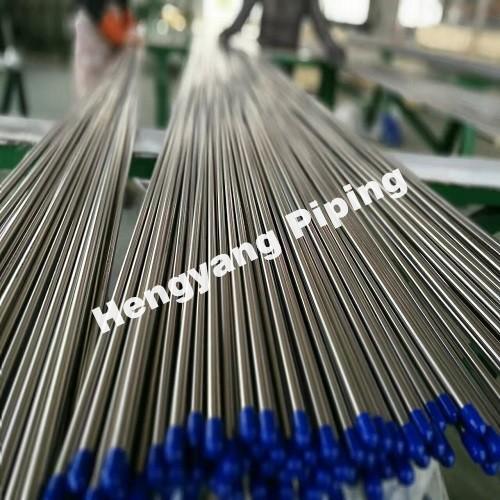

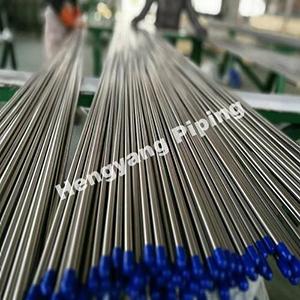

Precision tubes, also known as precision steel tubes, are high-quality tubes made with precise dimensions and tolerances. These tubes are manufactured using advanced technology and are widely used in various industries for their exceptional strength, durability, and precision. One specific type of precision tube is the bright annealed tube, which undergoes a specialized annealing process to achieve a bright, clean surface finish. In this article, we will explore what precision tubes are and their diverse applications across different sectors.

Precision tubes are manufactured with a high degree of accuracy in terms of their dimensions, thickness, and surface finish. These tubes are commonly made from materials such as stainless steel, carbon steel, alloy steel, and other special alloys. The manufacturing process involves cold drawing or cold rolling, which ensures the tubes have uniform dimensions and excellent surface quality. Additionally, the bright annealed tubes undergo a heat treatment process called annealing, which not only improves the mechanical properties of the tube but also imparts a bright, reflective surface finish.

The precision and high-quality attributes of precision tubes make them suitable for a wide range of applications. In the automotive industry, precision tubes are used in the manufacturing of fuel injection lines, hydraulic lines, and air conditioning systems. Their dimensional accuracy and resistance to corrosion make them ideal for these critical applications. Furthermore, in the aerospace sector, precision tubes are utilized in aircraft hydraulic systems, instrumentation, and control systems due to their reliability and high-performance characteristics.

In the energy sector, precision tubes find applications in the production of heat exchangers, boilers, and condensers. The ability of these tubes to withstand high temperatures and pressures makes them essential components in power generation and industrial heating systems. Moreover, in the medical industry, precision tubes are used in the production of surgical instruments, medical implants, and diagnostic equipment, where the highest standards of quality and precision are required.

The construction and architecture industries also benefit from the use of precision tubes in structural applications, such as in the fabrication of handrails, scaffolding, and architectural frameworks. The exceptional strength and dimensional accuracy of these tubes contribute to the overall safety and reliability of the structures in which they are used. Additionally, precision tubes are employed in the manufacturing of furniture, sports equipment, and various mechanical components across different sectors.

In conclusion, precision tubes, including bright annealed tubes, play a crucial role in numerous industries due to their precision manufacturing, high-quality attributes, and diverse applications. The exceptional dimensional accuracy, surface finish, and material properties of precision tubes make them indispensable in critical sectors such as automotive, aerospace, energy, medical, construction, and many others. As technology continues to advance, the demand for precision tubes is expected to grow, further emphasizing their significance in modern industrial applications.

For high-quality precision tubes and bright annealed tubes, please feel free to contact us, your trusted supplier for all your precision tube needs.