Difference Between Duplex and Stainless Steel

Duplex steel and stainless steel are two common types of steel used in various industrial applications. While both of them are corrosion-resistant, they have distinct differences in their chemical composition, microstructure, and mechanical properties. In this article, we will delve into the differences between duplex and stainless steel in more detail.

Chmical Composition

Duplex steel is a type of steel that contains both austenitic and ferritic phases in roughly equal proportions. It has a higher chromium content than standard austenitic stainless steel, which enhances its corrosion resistance. Duplex steel also contains significant amounts of nickel, molybdenum, and nitrogen, which contribute to its strength, toughness, and resistance to stress corrosion cracking.

On the other hand, stainless steel is a broad term that refers to a group of steel alloys that contain a minimum of 10.5% chromium by mass. The chromium content forms a passive oxide layer on the surface of the steel, which provides excellent corrosion resistance. Stainless steel also contains varying amounts of nickel, molybdenum, and other elements, depending on the specific grade and intended application.

Microstructure

Duplex steel has a unique microstructure that consists of a mixture of austenite and ferrite phases. The proportion of each phase can vary depending on the specific grade of duplex steel. The two phases provide duplex steel with a combination of high strength and excellent corrosion resistance. Duplex steel is also highly resistant to stress corrosion cracking, which makes it an ideal material for use in harsh environments.Stainless steel, on the other hand, has a homogeneous microstructure that consists of austenite, ferrite, or martensite phases. The specific microstructure depends on the specific grade of stainless steel and the processing techniques used during manufacturing. Austenitic stainless steel, for example, has a face-centered cubic (FCC) crystal structure, while ferritic stainless steel has a body-centered cubic (BCC) crystal structure. Martensitic stainless steel, which is the hardest and strongest type of stainless steel, has a body-centered tetragonal (BCT) crystal structure.

Mechanical Properties

Duplex steel has excellent mechanical properties, such as high tensile strength, good ductility, and excellent toughness. The combination of austenite and ferrite phases provides duplex steel with superior strength and corrosion resistance compared to austenitic or ferritic stainless steel. Duplex steel also has high resistance to stress corrosion cracking, which makes it ideal for use in marine environments and chemical processing industries.Stainless steel also has excellent mechanical properties, such as high strength, good ductility, and excellent toughness. The specific mechanical properties depend on the specific grade of stainless steel and the processing techniques used during manufacturing. Austenitic stainless steel, for example, has excellent formability and weldability, while martensitic stainless steel has the highest hardness and wear resistance.

Applications

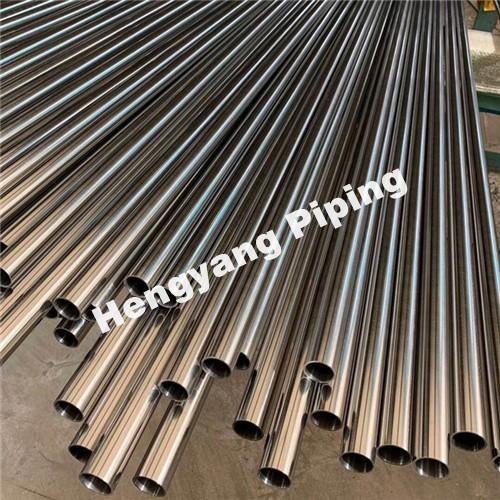

Duplex steel is commonly used in various industries, such as oil and gas, chemical processing, and marine engineering. It is often used to manufacture pipes, heat exchangers, pressure vessels, and storage tanks. Duplex steel is also used in the construction of bridges, offshore platforms, and other structures that require high strength and corrosion resistance.

Stainless steel is widely used in various industries, such as food processing, medical, automotive, and aerospace. It is often used to manufacture kitchen utensils, medical equipment, automotive parts, and aircraft components. Stainless steel is also used in the construction of buildings, bridges, and other structures that require corrosion resistance and aesthetic appeal.

Cost

Duplex steel is more expensive than stainless steel due to its complex manufacturing process and higher content of alloying elements like molybdenum and nitrogen. However, its higher strength and superior corrosion resistance make it more cost-effective in the long run, especially in harsh environments where frequent maintenance and replacement of equipment can be costly. Stainless steel is relatively cheaper than duplex steel, making it more suitable for applications that do not require high strength and corrosion resistance.

If you want to know more information about duplex steel, please contact us. We will provide professional answers.