Difference Between Stainless Steel Welded Pipe and Stainless Steel Seamless Pipe

Stainless steel pipes are crucial components in various industries, serving diverse purposes due to their durability, corrosion resistance, and reliability. Understanding the distinctions between stainless steel welded pipes and stainless steel seamless pipes is essential in selecting the right option for specific applications.

Manufacturing Process

Stainless Steel Welded Pipe

Stainless steel welded pipes are made by welding a rolled sheet of stainless steel into a tube using a welding process. The welding can be done using various methods, such as TIG, MIG, or electric resistance welding. The welded joint is then annealed to restore the material's corrosion resistance and strength. This welding process forms a strong bond between the edges, creating a solid and robust pipe.

Stainless Steel Seamless Pipe

On the other hand, stainless steel seamless pipes are crafted without any welding seams. These pipes are formed from a solid cylindrical steel billet through a process called extrusion or drawing. The billet is heated and pierced to create a hollow tube without any joints or seams, resulting in a continuous and uniform structure.

Structural Integrity and Strength

Stainless Steel Welded Pipe

Welded pipes exhibit excellent strength and durability due to the welding process that fuses the edges together. However, the welded seam might be susceptible to certain stresses and corrosion in comparison to seamless pipes.

Stainless Steel Seamless Pipe

Stainless steel seamless pipes boast superior structural integrity owing to their uninterrupted structure. Seamless pipes are generally stronger and more resistant to pressure, making them suitable for high-pressure applications such as oil and gas transportation or in industries where structural integrity is paramount.

Appearance and Surface Finish

Stainless Steel Welded Pipe

Welded pipes often showcase visible seams at the welded joint. While these seams are typically smooth and well-polished, they may not offer the same aesthetically pleasing appearance as seamless pipes.

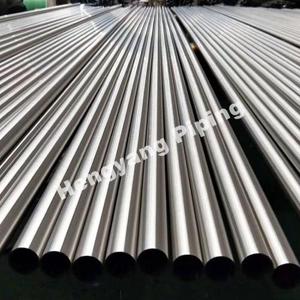

Stainless Steel Seamless Pipe

Seamless pipes present a smooth and uniform surface without any visible seams, providing a sleek and polished appearance. This seamless design makes them an ideal choice for applications where a flawless finish is desired, such as in architectural structures or industries requiring a visually appealing surface.

Cost Considerations

Stainless Steel Welded Pipe

In general, welded pipes tend to be more cost-effective compared to seamless pipes. The manufacturing process for welded pipes involves less complex machinery and shorter production times, resulting in a more budget-friendly option for various applications.

Stainless Steel Seamless Pipe

Conversely, the production of seamless pipes involves intricate manufacturing techniques and higher raw material costs due to the absence of welding. As a result, seamless pipes are typically pricier than their welded counterparts.

Application Specificity

Stainless Steel Welded Pipe

Welded pipes find their application in a wide array of industries such as construction, plumbing, and automotive. They are suitable for general-purpose uses where high pressure or extreme conditions aren’t a primary concern.

Stainless Steel Seamless Pipe

Seamless pipes are favored in industries where structural integrity, high pressure, and corrosion resistance are critical. These pipes are commonly employed in oil and gas, petrochemical, and aerospace industries due to their exceptional strength and reliability.

Conclusion

Both stainless steel welded pipes and stainless steel seamless pipes offer distinct advantages based on their manufacturing processes and specific applications. The choice between them depends on factors such as structural requirements, budget considerations, and the intended use case. Understanding these differences enables industries to make informed decisions when selecting the most suitable type of stainless steel pipe for their unique needs.