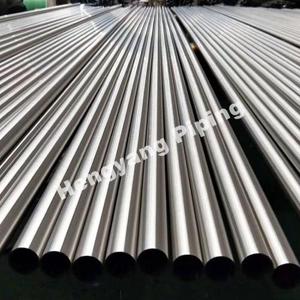

What Is Austenitic Stainless Steel Seamless Pipe?

Austenitic stainless steel seamless pipes are an integral part of modern engineering and industrial applications. Renowned for their exceptional corrosion resistance, superior strength, and versatility, these pipes are a cornerstone in industries like oil and gas, chemical processing, and construction. This article delves deep into the characteristics, manufacturing process, applications, and advantages of austenitic stainless steel seamless pipes, providing you with a comprehensive understanding of why they are indispensable in many critical operations.

What Are Austenitic Stainless Steels?

Austenitic stainless steels are a category of stainless steel alloys primarily composed of iron, chromium, and nickel, with small amounts of other elements such as manganese, nitrogen, and molybdenum. These steels are defined by their unique face-centered cubic (FCC) crystal structure, which remains stable at all temperatures.

The high nickel and chromium content in austenitic stainless steels makes them non-magnetic and grants them exceptional resistance to corrosion and oxidation, even in extreme environments. Common grades include 304, 316, and 310, each tailored for specific applications.

Key Features of Austenitic Stainless Steel Seamless Pipes

Here are some key features of austenitic stainless steel:

-Crystal structure: Austenitic stainless steel has an austenitic crystal structure, which is a face-centered cubic structure.

- Composition: A stable austenite structure is typically made up of about 18% chromium, 8% to 10% nickel, and about 0.1% carbon.

- Properties: Austenitic stainless steel is non-magnetic, has high toughness and plasticity, and is highly resistant to corrosion.

- Weldability: Austenitic stainless steel is known for its excellent weldability.

- Strengthening: Austenitic stainless steel can only be strengthened by cold working.

How Austenitic Stainless Steel Seamless Pipes Are Manufactured

1. Raw Material Selection

The process begins with selecting high-quality austenitic stainless steel billets, ensuring the chemical composition adheres to specific industry standards like ASTM A312.

2. Heating and Piercing

The billets are heated to a high temperature to achieve plasticity. They are then pierced using a rotary piercing machine, creating a hollow tube.

3. Elongation

The hollow tube undergoes elongation, which involves stretching it to the desired dimensions while maintaining uniform thickness.

4. Sizing and Finishing

The pipe is further processed to achieve precise dimensions, followed by heat treatment to enhance its mechanical properties and relieve internal stresses. The final steps involve pickling, polishing, and inspection to ensure compliance with strict quality standards.

Applications of Austenitic Stainless Steel Seamless Pipes

1. Oil and Gas Industry

These pipes are widely used in offshore drilling, pipeline systems, and refineries, where resistance to corrosion and high-pressure capabilities are crucial.

2. Chemical Processing

The chemical industry demands materials that can withstand highly acidic or alkaline conditions, making austenitic stainless steel pipes the ideal choice for reactors, heat exchangers, and storage tanks.

3. Food and Beverage Industry

Grades like 304 and 316 are commonly used in the food and beverage sector due to their non-reactive surfaces, ensuring sanitary conditions in processing equipment.

4. Power Generation

Austenitic stainless steel seamless pipes play a vital role in thermal and nuclear power plants, where high-temperature resistance is essential for steam and water systems.

5. Medical Equipment

Their biocompatibility and corrosion resistance make these pipes suitable for manufacturing medical devices and surgical instruments.

Advantages of Austenitic Stainless Steel Seamless Pipes

1. Leak-Proof Design

Seamless pipes lack welded joints, eliminating potential weak points and ensuring a leak-proof construction suitable for high-pressure systems.

2. Enhanced Durability

The absence of weld seams and uniform wall thickness improve the mechanical strength of the pipe, ensuring long-term durability even under extreme conditions.

3. Aesthetic Appeal

With a polished finish, these pipes offer an attractive appearance, making them ideal for architectural applications.

4. Easy Maintenance

The smooth surface of austenitic stainless steel prevents the accumulation of debris, making cleaning and maintenance straightforward.

5. Sustainability

Stainless steel is 100% recyclable, making these pipes an environmentally friendly option for various industries.

Choosing the Right Grade

The selection of the appropriate grade of austenitic stainless steel seamless pipe depends on the specific application requirements:

- 304: Offers general-purpose corrosion resistance; ideal for low-pressure systems.

- 316: Enhanced resistance to chloride corrosion; used in marine and chemical environments.

- 310: Superior high-temperature resistance; suitable for furnace components and heat exchangers.

Conclusion

Austenitic stainless steel seamless pipes are a benchmark in industrial efficiency and reliability. Their exceptional corrosion resistance, high strength, and versatile applications make them an invaluable asset in industries ranging from oil and gas to healthcare. By understanding the properties and advantages of these pipes, businesses can make informed decisions to optimize their operations.