Description

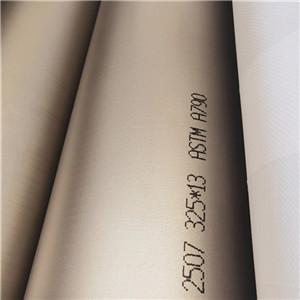

ASTM A312 Thin Wall/Light Wall Stainless Steel Seamless Pipes in 304/316/321

ASTM A312 is a specification for seamless and welded austenitic stainless steel pipes that perform well in high temperature and corrosive environments. Austenitic Stainless Steels are non-magnetic stainless steels that contain high levels of chromium and nickel and low levels of carbon. Known for their formability and resistance to corrosion, austenitic steels are the most widely used grade of stainless steel.

What is considered a thin-walled pipe?

Pipes with D/T greater than 20 are referred to as thin-walled pipes, and that with D/T less than 20 are called thick wall pipes.

A312 pipe features:

1. Austenitic Stainless Steel Excellence:

ASTM A312 pipes are made from non-magnetic austenitic stainless steels, renowned for their exceptional chromium and nickel content.

These high levels of chromium and nickel grant unparalleled corrosion resistance and robust durability.

Formability is a hallmark of austenitic steels, making them the top choice for intricate and demanding applications.

2. Seamless and Welded Precision:

ASTM A312 stainless steel pipes are available in both seamless and welded pipes, offering you the freedom to choose the ideal fit for your project.

Seamless pipes ensure a smooth, uninterrupted flow, reducing friction and minimizing the risk of leaks.

Welded pipes are meticulously crafted, ensuring structural integrity even in the most demanding conditions.

Wall Thickness: Sch 5S, Sch 10S, or as per clients' requirement.

Main Grades: 304/L, 304H, 304LN, 321/H, 316L, 316Ti, 316H, 316LN, 316LMOD, 310S, 310H, 317L, 347H, 347HFG, 309S, 904L, S31254 (254SMO) etc.

What's the application of stainless steel seamless thin wall pipes?

SS thin wall pipes are used for chemical , petroleum, light industry, food, mechanical, instrument, structrual parts etc..

1. Chemical Industry:

Resistant to corrosive chemicals, thin wall stainless steel pipe is a staple in chemical processing plants.

They provide a reliable conduit for transporting various chemicals, ensuring safety and product integrity.

2. Food and Beverage Sector:

In food and beverage production, hygiene is paramount. astm a312 stainless steel pipe maintains product purity, meeting stringent industry standards. Ideal for conveying liquids and ingredients safely.

3. Marine Environments:

Saltwater and harsh marine conditions are no match for the corrosion resistance of stainless steel pipe astm a312. They are trusted in shipbuilding and offshore applications.

4. Mining Operations:

The ruggedness of ASTM A312 pipes makes them essential in mining operations. They withstand abrasive materials and maintain structural integrity deep underground.

5. Oil and Gas Exploration:

In the oil and gas industry, reliability is non-negotiable. Our thin wall ss tubing excels in high-pressure, corrosive environments. They are used in drilling, production, and transportation of hydrocarbons.

6. Pharmaceutical Manufacturing:

Pharmaceuticals demand precision and purity. A312 pipes are integral in pharmaceutical manufacturing, maintaining product integrity.

7. Petrochemical Plants:

Petrochemical plants rely on our pipes for their resistance to aggressive chemicals and high temperatures. They are pivotal in the production of petrochemical products.

8. Power Generation:

Power plants require pipes that can withstand extreme heat and pressure. ASTM A312 pipes are up to the task. They ensure efficient energy generation.

9. Renewable Energy:

In renewable energy sectors like solar and wind, thin wall pipes are used in critical components due to their durability and corrosion resistance.

Standards(Part):

ASTM A269 Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

ASTM A270 Standard Specification for Seamless and Welded Austenitic and Ferritic/Austenitic Stainless Steel Sanitary Tubing

ASME SA249 Welded Austenitic Steel Boiler, Superheater, Heat Exchanger, and Condenser Tubes.

ASTM A312 Seamless and Welded Austenitic Stainless Steel Pipes

ASTM A358

JIS G3463

JIS G3459

GOST 9941-81

DIN 17456-8599

...