Description

BA Tube/ Precision Tube/ Instrument Tube/ Sanitary Tube / Coiled Tube

When precision, corrosion resistance, and exceptional quality are non-negotiable, turn to our bright annealed stainless steel tube. Crafted with expertise and designed for versatility, this stainless steel tube is an essential component in various industries.

Size: OD: 0.12mm-203.2mm

WT:

0.015mm-10mm

Material: Austenitic Stainless Steel: 304,

316L, 316Ti etc.

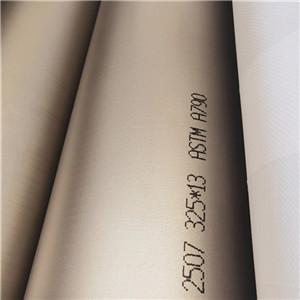

Duplex/Super Duplex Steel: S32205, S32750

Nickel Alloy: Monel 400, Inconel 625, Inconel

600, Inconel 601

Hastelloy C276, Alloy 825 ect.

Bright Annealed Tube Advantages:

1. Smooth and Corrosion-Resistant: The bright annealing process leaves no room for compromise. By heating the stainless steel material in a controlled environment and subsequently cooling it rapidly, a protective layer forms on the surface, ensuring optimal corrosion resistance even in challenging environments.

2. Superior Surface Finish: Precision stainless steel tubing boasts a surface that's not only smooth but also non-oxidizing. This results in a polished finish that is not only visually appealing but also resistant to corrosion, maintaining its shine over time.

3. Precision Engineering: Expect nothing but precision with stainless steel BA tube. It adheres to stringent dimension tolerances, making it an ideal choice for applications where accuracy is paramount.

4. Minimal Oxidation: With the controlled atmosphere of bright annealing, oxidation is kept to a minimum. As a result, there's no need for pickling after the process, making the surface even smoother and enhancing its resistance to pitting corrosion.

Precision Tubing Types:

Bright Annealing Welded Tube: In this process, precision welded tubes are annealed in a vacuum-controlled atmosphere to maintain a surface free of oxidation and brightness. A protective gas, typically purified hydrogen or a mixture of hydrogen and nitrogen, is used. The result? A bright and smooth protective layer that enhances corrosion resistance.

Bright Annealing Seamless Tube: Crafted from stainless steel billets through a coil coiled and coil drawn process, seamless precision steel tube undergo a critical annealing stage. Bright annealed seamless tubing, specified according to ASTM A269, ensures uniform structure and stress elimination. Ideal for applications requiring precision, it is annealed using an offline annealing furnace.

Bright Annealed Tube Applications:

1. Medical Components:

Our precision tubing is essential in the medical industry, where biocompatibility and precision are paramount. It is used in the manufacturing of various medical devices and components.

2. Temperature Sensing:

Reliable in various industries, precision steel tubes are used in temperature sensing equipment, ensuring accurate temperature measurements and control.

3. Food Equipment:

Designed to meet hygiene and corrosion resistance requirements, precision steel pipes are a staple in food processing and handling equipment, ensuring safety and longevity.

4. Gas and Oil Refinery Components:

Capable of handling corrosive environments, precision seamless steel pipes are used in gas and oil refineries, providing durability and reliability in harsh conditions.

5. Water Quality Instrument Components:

Precision stainless tubing is integral in water quality instruments, ensuring accurate water analysis and monitoring.

6. Nuclear Energy Components:

In the nuclear energy sector, where safety and durability are non-negotiable, our precision tubing is used in critical components, providing the necessary reliability and longevity.

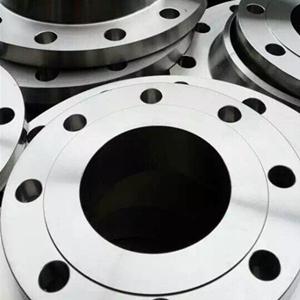

Stainless steel is available in wide variety of shapes and forms including pipe, tube, fitting, flange, sheet, plate, round bar, forging stock, flat bar, wire, hexagon. The various forms of pipe fittings from Hengyang Piping meet different critical standards like ASTM, ASME, DIN, EN, ISO and clients’ specification. For detailed information about customized pipe and fittings, please contact us!