Description

The high-pressure heat exchangers and low-pressure water supply condensers of large power plants are assembled and manufactured by completing U shaped steel tubes with different radii. The U shaped steel pipe has a smaller diameter, thinner wall and longer length. High- and low-pressure heat exchanger tubes, extra-long stainless steel U tubes production standards: ASME SA688

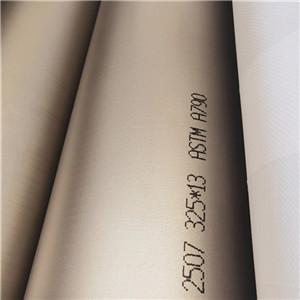

Ultra-long U bend stainless steel tubes are made of ASTM A688 TP304/304L with superior structural integrity. The ss u tubes are meticulously crafted and rigorously tested to meet the highest industry standards. With dimensions of 15.88mm in outer diameter and a wall thickness of just 0.71mm, these duplex stainless steel pipes come in straight lengths ranging from 20525mm to 22046mm, making them an exceptional choice for high-performance condenser equipment.

Stainless steel u tubes features

1. Ultra-Thin Wall Thickness: Our stainless steel u pipes feature an ultra-thin wall thickness of 0.71mm, a rare attribute for such extended lengths.

2. Extended Lengths: Available in lengths from 20525mm to 22046mm, surpassing typical market offerings.

3. Seamless Construction: Unlike common welded tubes, ASTM A688 tubes are seamless, providing superior structural integrity.

4. Precision Engineering: Designed to meet stringent specifications, ASTM A688 pipes are especially in U-bend sections with small radii.

Technical Specifications

|

Specification |

Details |

|

Manufacturing |

Cold Rolled / Cold Drawn |

|

Type |

Seamless / Welded |

|

Surface |

Annealed and Passivated, Bright Annealed |

|

Third Party Inspection |

Available |

|

Maximum Length |

30 meters |

|

Outer Diameter |

15.88 mm |

|

Wall Thickness |

0.71 mm |

|

Developed Length |

20525mm to 22046mm |

|

Material |

Stainless Steel, Duplex/Super Duplex, Nickel Alloys, Titanium Steel,CS |

Material Availability

|

Material Category |

Grades Available |

|

Stainless Steel |

304, 321, 316, 316Ti, 317L, 904L, S31254, 310S, TP446 |

|

Duplex/Super Duplex |

S31803/32205, S32750, S32760, S32304 |

|

Nickel Alloys |

Inconel 625, 600, Incoloy 825, 800, Monel 400, Hastelloy C276, C22 |

|

Titanium Steel |

Gr.1 Gr.2 Gr.3 Gr.7 Gr.9 Gr.11 Gr.12 Gr.16 Gr.17 |

|

Carbon Steel |

T11, T22, T91, T5, T9 |

Manufacturing and Quality Control

1. Cold Rolled / Cold Drawn: Utilizing advanced cold rolling and drawing techniques to achieve precise dimensions and superior finish.

2. Surface Treatment: Stainless steel U bend pipes are annealed and passivated to enhance corrosion resistance and surface quality.

3. Inspection: Third-party inspection services are available to verify compliance with stringent quality standards.

4. Specialized U-Bending: Expert handling of small radius U-bends ensures the tubes maintain their structural integrity and performance under demanding conditions.

Stainless steel u tube applications

These ultra-long, ultra-thin wall stainless steel u pipes are specifically designed for use in high-performance condenser equipment. Unique properties make them ideal for industries where precision, durability, and reliability are critical.

Company Advantage

1. Production Capability: Very few manufacturers in the industry are able to produce this type of thin-walled, extra-long seamless pipe.

2. Superior Quality: Stringent quality control and specialized manufacturing processes ensure the highest standards of u bend steel tubing.

3. Custom Solutions: Hengyang Piping provides tailored solutions to meet specific customer requirements, especially in challenging applications.

For further inquiries and detailed specifications about wholesale stainless steel u tubes, please contact us.