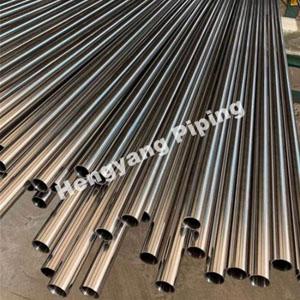

What Are Stainless Steel Hollow Bars?

Stainless steel hollow bars are a crucial component in various industries, valued for their durability, corrosion resistance, and versatility. These cylindrical tubes, distinguished by their empty center, offer unique properties that make them ideal for a wide range of applications. From construction to manufacturing, stainless steel hollow bars play a vital role in numerous sectors.

A hollowbar, as its name implies, is a metal bar with a central bore running the entire length. These bars are manufactured similarly to seamless tubes, being extruded from a forged bar and subsequently cut into the desired shape.

This manufacturing process endows the bar with excellent mechanical properties, typically resulting in enhanced consistency and impact toughness compared to rolled or forged components. Moreover, this material type typically boasts excellent uniformity of shape and dimensional tolerances.

Composition of Stainless Steel Hollow Bars

Stainless steel hollow bars are typically made from an alloy of iron, carbon, and a minimum of 10.5% chromium content. This chromium content forms a protective oxide layer on the surface of the steel, known as the passive layer, which provides exceptional corrosion resistance, even in harsh environments. Additionally, stainless steel hollow bars may contain other elements such as nickel, molybdenum, and manganese, depending on the specific requirements of the application.

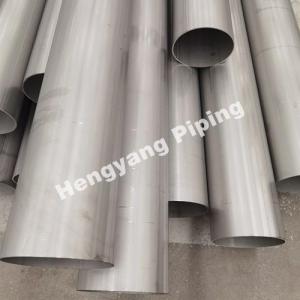

One of the primary advantages of stainless steel hollow bars is their superior strength-to-weight ratio. This makes them an excellent choice for structural components where both strength and lightness are essential, such as in aerospace and automotive applications. Furthermore, stainless steel hollow bars exhibit excellent machinability and weldability, allowing for easy fabrication into various shapes and sizes to meet specific project needs.

Unique Characteristics of Stainless Steel Hollow Bars

The primary distinction between a stainless steel hollow bar and a seamless tube lies in the wall thickness. Tubes are engineered and manufactured for fluid transport, limiting machining to the ends only for couplings or connectors. Conversely, hollow bars typically feature a thicker wall, facilitating the machining of various finished components.

Adopting hollow bars instead of solid ones offers direct savings in material and tooling expenses, along with reduced machining time and enhanced productivity. With near-net-shaped hollow bars, less metal is wasted as low-value swarf, and less tooling is consumed, resulting in immediate cost savings.

Moreover, reducing or eliminating machining steps can significantly boost manufacturing productivity. This can manifest as reduced machining time or costs for a given part, or increased throughput when machines are fully utilized. Additionally, substituting solid bars with stainless steel hollow bars eliminates the need for trepanning when producing components with a central bore, mitigating material work hardening and improving subsequent machining operations.

Applications

Stainless steel hollow bars find widespread use across diverse industries due to their exceptional properties. Some common applications include:

1. Construction: Stainless steel hollow bars are frequently used in construction for structural support, especially in high-rise buildings and bridges. Their corrosion resistance ensures longevity, even in challenging environmental conditions.

2. Manufacturing: In manufacturing processes, stainless steel hollow bars are utilized for the production of components in machinery, equipment, and tools. Their durability and resistance to wear make them suitable for demanding industrial applications.

3. Oil and Gas: The oil and gas industry relies on stainless steel hollow bars for drilling equipment, pipelines, and offshore platforms. The corrosion resistance of stainless steel ensures the integrity of critical infrastructure in harsh offshore environments.

4. Chemical Processing: Stainless steel hollow bars are integral to chemical processing applications where resistance to corrosion from harsh chemicals is paramount. They are used in the construction of reactors, vessels, and piping systems for handling corrosive substances.

5. Medical Devices: In the medical field, stainless steel hollow bars are employed in the manufacture of surgical instruments, implants, and medical devices. Their biocompatibility, coupled with corrosion resistance, makes them suitable for use within the human body.

Advantages of Stainless Steel Hollow Bars

Stainless steel hollow bars offer several advantages over other materials, including:

- Corrosion Resistance: The chromium content in stainless steel forms a protective oxide layer, providing excellent resistance to corrosion, rust, and staining.

- Strength and Durability: Stainless steel hollow bars exhibit high tensile strength and toughness, making them durable and long-lasting.

- Hygienic Properties: Stainless steel is easy to clean and maintain, making it ideal for applications requiring strict hygiene standards, such as in food processing and pharmaceutical industries.

- Aesthetic Appeal: Stainless steel hollow bars have a sleek, modern appearance, making them a preferred choice for architectural and decorative applications.

Conclusion

Stainless steel hollow bars are indispensable in various industries, offering unmatched durability, corrosion resistance, and versatility. From construction to medical devices, these cylindrical tubes serve a multitude of purposes, contributing to the efficiency and reliability of countless applications. With their superior properties and wide-ranging applications, stainless steel hollow bars continue to be a vital component in modern engineering and manufacturing processes.

For inquiries about stainless steel hollow bars or to find a reliable supplier, please don't hesitate to contact us.