Description

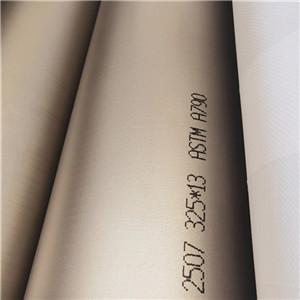

Alloy 904L•UNSN0904•WNR 1.4539

Alloy 904L is an austenitic stainless steel. In comparison to 316L, its molybdenum addition gives it superior resistance to localized attack (pitting and crevice corrosion) by chlorides and greater resistance reducing acids, in particular, its copper addition gives it useful corrosion resistance to all concentrations of sulphuric acid. Its high alloying content also gives it greater resistance to chloride stress corrosion cracking, but it is still susceptible. Its low carbon content makes the 904L stainless steel pipe resistant to sensitization by welding and which prevents intergranular corrosion.

Alloy 904L Chemical Composition

|

% |

Ni |

Cr |

Fe |

Mn |

C |

Cu |

Si |

S |

P |

N |

Mo |

|

Min |

23.0 |

19.0 |

balance |

|

|

1.0 |

|

|

|

|

4.0 |

|

Max |

28.0 |

23.0 |

2.0 |

0.020 |

2.0 |

1.0 |

0.03 |

0.04 |

0.1 |

5.0 |

UNS N08904 Physical Constants:

|

Density |

7.95 Mg/m³ |

|

Melting Range |

1300-1390 ℃ |

Advantages of Alloy 904L Stainless Steel Pipe

1. Corrosion Resistance: Alloy 904L stainless steel pipe boasts extraordinary resistance to acids, such as sulfuric acid, phosphoric acid, and acetic acid, making it an ideal choice for corrosive environments.

2. High Strength: This 904l pipe provides excellent strength and toughness, ensuring reliable performance even under extreme conditions.

3. Heat Resistance: Alloy 904L tubing exhibits exceptional heat resistance, making it suitable for applications involving elevated temperatures and thermal cycling.

4. Weldability: The weldability of 904l stainless steel tube is excellent, allowing for easy fabrication and installation.

5. Low Carbon Content: With a low carbon content, Stainless Steel Alloy 904L offers superior resistance to intergranular corrosion, enhancing its durability and longevity.

Applications of Alloy 904L Stainless Steel Pipe

1. Heat Exchangers: Alloy 904L pipes are extensively used in heat exchangers due to their excellent resistance to corrosion and high thermal conductivity.

2. Condenser Tubes: These stainless steel 904l tubes are widely employed in condenser systems, where the resistance to chloride-induced corrosion is crucial for optimal performance.

3. Pulp and Paper Processing Industries: SS 904l pipe is highly sought after in pulp and paper processing applications due to its resistance to sulfuric acid and chloride-containing chemicals.

4. Oil Refinery Components: The superior corrosion resistance of Alloy 904L makes it an excellent choice for various oil refinery components, including pipes, fittings, and storage tanks.

5. Gas Scrubbing Plants: 904l stainless steel tubes find extensive use in gas scrubbing plants, where their exceptional resistance to acids and harsh chemicals is vital for efficient operations.

Whether you require Alloy 904L pipe or 904L stainless steel tubing, we offer a comprehensive range of sizes and specifications to meet your specific requirements. Our stainless steel 904l pipes are manufactured using state-of-the-art technology and undergo rigorous quality checks to ensure reliability and durability.

As one of the experienced 904l pipe suppliers, Hengyang Piping is are committed to providing exceptional products and unparalleled customer service. Contact us today to discuss your project needs and let our expert team assist you in finding the perfect solution with Alloy 904L pipe.